Table of Contents

This is an old revision of the document!

REF: Service Procedures 26

Squish Band

The squish (AKA “quench”) band refers to the area or areas,

where the piston comes very close to the cylinder head while passing through top dead center (TDC). 1)

2)

2)

Even though the fire has already been lit, these areas still contain unburned air/fuel mix as the piston arrives.

The piston sandwiches the air/fuel up next to the head, causing it to “squish”, and shoot out toward the flame front.

The result is more chamber turbulence, better atomization of the fuel, and the squish band even has a cooling effect on the fuel.

They result in more complete combustion (more power and better fuel mileage) as well as better resistance to detonation.

The squish band clearance would normally probably be in the .040“ to .060” range from the factory.

But when you put it together yourself, you can take some extra time and effort and optimize certain things.

Ideally you'd like it more on the order of .030“ (or .035” if you're using a full cast iron cylinder).

You can optimize the squish band by adjusting the height of the cylinder head relative to the piston.

(such that the piston come closer to the head)

This will give you a little free power, better mileage, and more resistance to detonation.

If you let it get too close, you can actually get contact due to things like thermal expansion and piston rock.

When 883 heads are used over the larger 3-1/2“ 1200 bore or 3-9/16” bore 1250 cylinders, a squish band is gained around the perimeter of the chamber.

Measuring the Squish Band

Indirect Method

You can use a piston height gauge to measure how far above or below the cylinder deck the piston is sitting at TDC.

Then add that measurement to the gasket thickness.

This method works fine with both decks being flat.

But it doesn't work well with heads that have angled domes.

Direct Method

You'll be placing some soft material, such as .065“ solder, onto the squish band area of the piston.

(clay has been used for this also but it's not as accurate as using solder which won't change thickness)

Rotate the engine through TDC, remove the material, and measure it's thickness.

It takes more time than measuring the deck as in above because it requires an extra disassembly/reassembly cycle of the cylinder head.

But this method works great with flat or angled head surfaces. The tools required are no more than if you are installing the heads.

Gaining a Squish Band Due to a Conversion

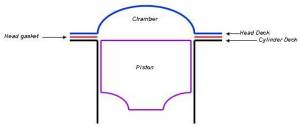

An 883 head has a hemi chamber with no squish band but it's chamber is only 3” in diameter to match the 3“ bore size of the 883. 3)

What's fundamentally wrong with the hemi design is that it gives very poor chamber turbulence.

Poor chamber turbulence means poor air/fuel mixing, resulting in pockets of fuel.

It makes the chamber detonation prone. For this reason, all the hemi-chamber XL motors are & were limited to 9:1 compression.

(all 883's, and 88-03 1200's that is except 1200S models which had Buell lightning heads and 10:1 compression)

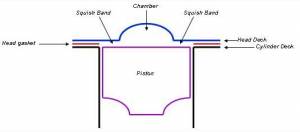

However, when you do a conversion, a very good side effect is that you gain a squish band around the perimeter of the chamber.

This is because you're now putting a 3-1/2” (1200) or 3-9/16“ (1250) diameter piston under that hemi chamber.

Now with the squish band and as the piston passes through TDC,

Air & fuel that's trapped between the head and the piston in the “squish band” gets squeezed out.

(like stepping on a tube of toothpaste).

The result is more chamber turbulence resulting in better mixing, better efficiency, and less detonation.

In fact most people move to 10:1 compression when doing a conversion because the better chamber turbulence makes it possible.

Machined Squish Band

| Piston and head with matched squish band. 6) |

|

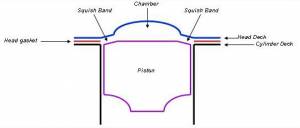

A piston with a reverse dome has a dish in the middle of it.

That dish is needed because when doing a conversion, you've got a chamber that's sized for an 883 and a piston that's sized for a 1200 or 1250.

That has the effect of greatly increasing compression ratio.

In order to make this combination work at 10:1, the piston needs a dish in the top of it as shown below.

Also notice how the piston has a shelf around it's perimeter that's about a quarter inch wide.

That's to meet the underside of the head and create the squish band.

The reverse dome conversion pistons below are a “bolt-in”, meaning they require no head work, they're made to work with stock 883 heads.

As good as all this is, it's not ideal.

The squish surface area, as a percentage of the total area of the chamber, runs about 25%.

You'd like more on the order of 35% for optimum chamber turbulence.

You can buy 30° reverse dome pistons and get the heads machined to match the piston angle.

Notice the head below has an angled dome all the way around it's perimeter.

This angle is fairly steep at 30° to match the 30° angled piston squish surface.