Table of Contents

REF: Service Procedures 20

Cylinder Compression Test

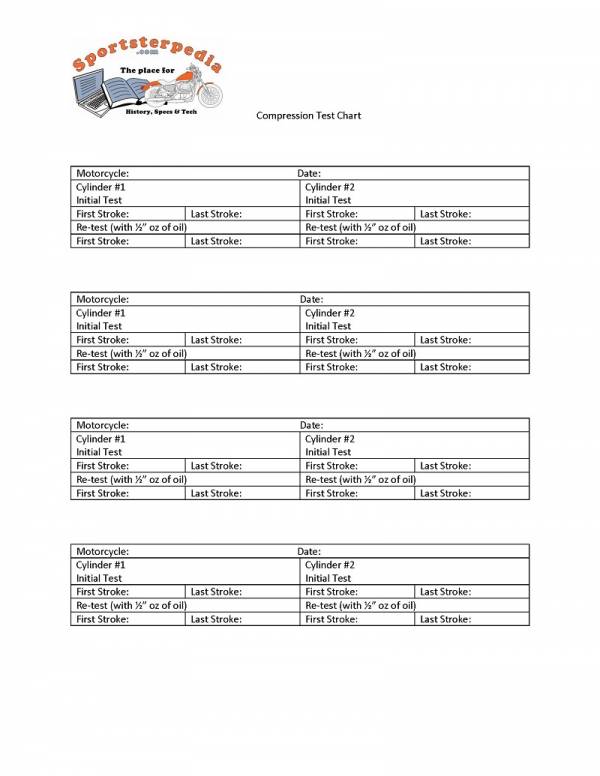

A compression test should be done as part of each tune-up. Record the results and follow any changes over time. 1)

- The compression tester has a one-way valve in it's hose, allowing it to see the pressure of the compression stroke

but not relieve it on the other strokes. Additional strokes that produce higher pressures will increase the

reading of the gauge. - Always look for a compression tester that has it's check valve as near to the chamber as possible. Otherwise, you're

adding the volume of the hose (up to the check valve) to the chamber volume which causes the compression reading

to be lower, because the piston is trying to fill that hose space as well as the chamber. 2) - A proper compression test should be done with the engine close to normal operating temperature, when possible. 3)

Compression Test vs Leak-Down Test

- These are both fancy names for a deceptively simple process (installing an air gauge in the spark plug hole and noting the results). 4)

- A compression test checks the cylinder's maximum pressure ability. A low reading reflects poor sealing of the chamber.

- Generally if a compression test shows anything suspect, the next step is a leak down test. 5)

- A leak-down test checks the cylinder's ability to hold pressure (seal) and will reflect where the leak is occuring.

- See also Performing a Leak-Down Test in the REF section of the Sportsterpedia.

Test Each Cylinder for Compression

- Ride the bike to get the engine up to operating temperature. 6)

- Disconnect the power to the coil to prevent it from firing.

- The extra two plugs (on dual plug heads) need to remain in place during this test. 7)

- If you can't disconnect power to the coil, ground out all the plug wires.

- Clean the area around the spark plugs BEFORE you remove them. 8)

- If you haven't disconnected the coil, you can insert the plugs into the plug wires and press the plugs against the cylinder heads for grounding. 9)

- Connect the compression gauge to the first cylinder.

- Make sure the throttle plate is fully open (and the choke, if present) before turning over the engine.

- If using a CV carb, hold the slide up. 10)

- If the cylinder can't freely pull in air, the compression reading will be low.

- Do NOT pull the enrichener knob - The enrichener is mis-named a choke ('86-'06) but it is not a choke plate.

- Crank the engine continuously through 5-7 compression strokes. (until there is no further increase in reading at the gauge) 11)

- Record the readings at the end of the first and last strokes for this cylinder.

- If you get a lower than normal reading, add app. 1/2 ounce of oil into the cylinder, repeat the compression test to see if the reading will increase. Record the oil-added readings.

- Repeat for the second cylinder.

Interpreting the Readings

- Compare the readings for both cylinders.

| Table of Expected/Acceptable Readings for Evo Engine Models | ||||

| Model Years | 883cc Engines | 1200cc Engines | ||

| 1986-2003 | 120psi Min | 9.0:1 CR | Not in Manual, but expect 150psi or greater | 9.0:1 CR |

| 1200 Sport Model → | Not in Manual, but expect 200psi or greater | 10.0:1 CR | ||

| 2004-2008 | 120-140psi | 8.9:1 CR | 200-225psi | 9.7:1 CR |

| 2009-later | 165-180psi | 8.9:1 CR | 200-225psi | 9.7:1 CR |

| Notes: The recorded results between the two cylinders should be within 10psi of each other. PSI expectations are from HD manuals. |

||||

- Also, pay attention to how many pumps it takes to pump up each cylinder. 14) Both cylinders should be relatively comparable.

- Pumping up too fast means the exhaust isn't opening (pushrod worn too much or loose enough to fall out of place).

- Pumping up too slow is the usual suspect list below:

| Possible Ring problems | Compression low on 1st stroke tending to build up on following strokes without reaching normal spec. Improves considerably with a re-test with oil |

| Possible Valve problems or Head Gasket Leak | Compression low on first stroke tending to not build up on following strokes even with a re-test with oil |

If you have low test results, go back through the steps above and re-test before moving on to the Leak-Down Test.

Tracking Your Test Results

Compression Test Results from XLFORUM Members

Member:

sep69

Engine: 2002 883R > 1250R conversion.

Compression Test Results:

Front Cylinder: 270 psi.

Rear Cylinder: 55 psi.

Symptoms:

Sudden rattling noise in engine with noise increasing.

White smoke coming from the A/C and pipes.

Oily spark plugs.

Actions:

Immediate disassembly of the rear cylinder.

Results Upon Disassembly:

The exhaust side of the rear piston was broken and missing.

Possible Cause:

Piston ring gap too tight upon installation. 15)

Full Article: https://www.xlforum.net/forum/sportster-motorcycle-forum/sportster-motorcycle-motor-engine/sportster-motorcycle-bottom-end/144544-white-smoke-from-pipe-and-ac-rattle-in-engine?t=1567509

Pics of the Damage: 16)

Compression Calculator

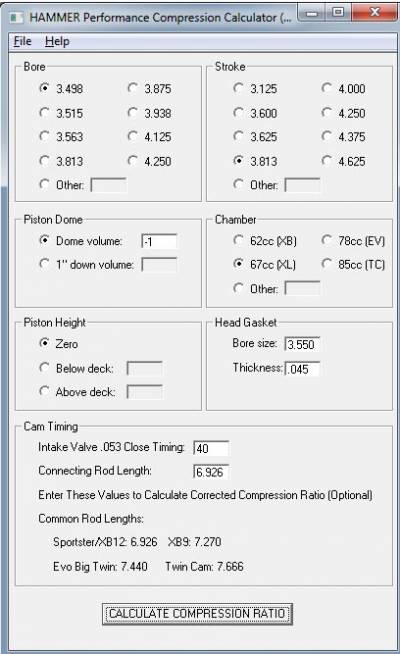

Article by aswracing of the XLFORUM 17) and Hammer Performance site. 18)

Click here to download a free copy of the HAMMER PERFORMANCE Compression Calculator.

So how much compression can you run with what cams, and still be able to run pump gas?

This question comes up from time to time on the XLFforum.

And unfortunately, the answers tend to either be inaccurate, incomplete, or just downright vague.

The right answer is that you should figure out your corrected compression ratio.

Which is the compression ratio of the motor considering the intake valve close timing.

In a nutshell, as the piston starts the compression stroke, the intake valve is still hanging open.

Until the intake valve closes, no compression will be built.

What corrected compression ratio tells you is what CR you have after the intake valve closes.

This is the number to look at when deciding if your bike is going to run okay on pump gas.

So how do you figure it out? Well, it's not as simple as it sounds at first.

The big end of the rod travels in an arc and the connecting rod is not infinitely long.

So you end up with a non-linear relationship between piston position and crankshaft rotation.

For example, in the first 10 degrees after bottom dead cylinder, the piston barely moves at all.

By comparison, 10 degrees of crank rotation that happens after the piston is halfway up causes a relatively large amount of piston movement.

It's basically a geometry problem.

To solve the problem, you need to dust off your trigonometry textbook and make right triangles out of it.

Or, you could take the easy way and just download the calculator.

Store the file somewhere on your hard drive where it's easy to find, and then double click on it to execute.

The program is very easy to use, and it will give progressively more info as you enter more data:

- For just displacement, enter the bore and stroke.

- To also get static compression ratio, enter the piston dome, chamber size, piston height, and gasket specs.

- To also get corrected compression ratio, enter the intake close point (.053 lift crankshaft degrees) and connecting rod length.

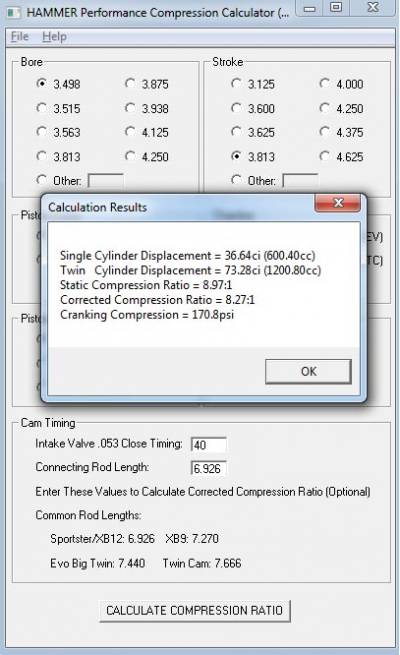

This program calculates both static and corrected compression ratio. What's the difference? 19)

The static compression ratio takes the full compression stroke into account. This is the standard way of doing it.

The corrected compression ratio, however, only counts the portion of the compression stroke after the intake valve closes.

Corrected compression ratios of around 9.2:1 are considered the max you can run on U.S. pump gas, with a reasonably turbulent chamber.

Since no compression builds until after the intake valve closes,

It's the corrected compression ratio that gives the best indication of how pump gas friendly your motor will be.

Premium pump gas in the U.S. will generally tolerate corrected compression ratios of somewhere between 8.8:1 and 9.3:1.

With a poor chamber that has little turbulence ( i.e hemi chambers and no squish band), stay on the low end of that range, maybe even lower.

With a good, turbulent chamber (think squish bands), you can run more toward the high end of the range.

With good chamber turbulence and dual plugs, you can even run it higher, up to 9.5:1 is not unusual.

This is a free tool, independently developed in-house by Hammer Performance 20).

Feel free to use it and distribute it as you please.

It's virus-free.

It collects no information about you or phones, home or anything like that.

All it does is perform the calculations and give you the answer.

Note that results given by this program are intended as a guideline only.

HAMMER PERFORMANCE assumes no responsibility for what you do with the information presented.