Table of Contents

This is an old revision of the document!

REF: Service Procedures 11K

Calculating Gear Ratios

General Information

If you are researching how to calculate gear ratios, it can be confusing since there are several ways to come to the same answer. And once there were general practices that have gotten skewed by the years since. But math doesn't change, only the way you look at it does. Simple math is all that is needed to find the different ratios and information about the gear train. Simple formulas are used to achieve this. The trouble can be which formula to use for what purpose.

Some information regarding car/truck ratios is relevant but a large portion is not due to the different type transmission setups there are as opposed to Sportsters. And some motorcycle information is the same depending on what type/size/make etc. as opposed to Sportsters. Then you eventually start finding engineering information which is more science related to general subjects and you have to pick out what you can from that.

This article intends to at least try and zero in on helpful information to the average Sportster owner.

If there was only one gear on a shaft, there'd be no need to find a ratio. You know how many turns are made based off the RPM of the gear shaft. When you add a second gear and shaft with gear teeth meshed to the first and both are different sizes, one will turn at a different speed than the other. Therefore, their respective shafts will also turn at different speeds.

Worth noting is that the actual power source to the transmission can change during a ride.

The input source to the transmission with the clutch engaged (clutch lever released) is the engine. When you are on the throttle, the motor is driving the transmission and thus the rear tire. The motor is driving the mainshaft and it's gears, and the mainshaft gears are driving respective countershaft gears and thus the rear tire. The input source to the transmission with the clutch disengaged (clutch lever pulled) is the rear tire. When you disengage the clutch, the motor is now not attached to the transmission but the transmission gears still turn. The rear tire is now driving the countershaft and it's gears which turn their respective mainshaft gears. When you let off the throttle with the clutch engaged (lever released), the rear tire is still trying to drive the transmission at the speed the motor was before pulling the clutch. So there is a push/pull going on inside the transmission while riding depending on throttle load.

How to Read Factory Specs

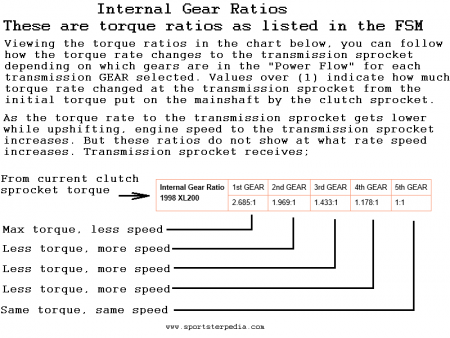

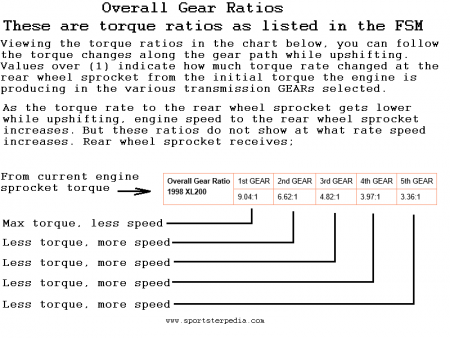

The “Gear Ratios” given in the “Transmission Specification” page in the FSM all relate to Torque, not speed.

It is Harley Davidson that spurs the initial confusion.

The manuals state verbiage like “Internal gear ratios indicate number of mainshaft revolutions required to drive output sprocket one revolution.” This verbiage refers to speed (or RPM) but the ratios listed are all torque ratios. And the service manuals list the different internal ratio values for (i.e. for 883 and 1200) engines. The manuals also state “Overall gear ratios indicate number of engine revolutions required to drive the rear wheel one revolution”. This verbiage also refers to speed (RPM) and the ratios given in the manual are all torque ratios.

If you run the numbers yourself, you'll find the GEAR RATIO does not match the specs they list in the manuals. The gear ratio formula represents a change in speed due to the different number of teeth on the driven gear as opposed to number of teeth the driver gear. So you divide the number of teeth on the driver gear BY the number of teeth on the driven gear and you find how much faster or slower the driven gear turns as opposed to the driver gear. In contrast, using the INVERSE of the GEAR RATIO reveals a mechanical advantage (or disadvantage depending on the result). It represents the leverage (or torque in this application) gained or lost by the teeth count on the driven gear. To calculate mechanical advantage (or torque ratio), you simply reverse the gear ratio formula and divide the number of teeth on the driven gear BY the number of teeth on the driver gear. If you count the gear teeth on the pertaining gears and use the INVERSE GEAR RATIO FORMULA, you'll find that Harley lists the torque ratios for “internal gear ratios” and “overall

gear ratios” in the manuals.

How to read the overall ratios in the FSM; 1)

General Terminology

Gear Ratio vs Inverse Gear Ratio

The standard gear ratio tells you how fast the second gear (driven gear) turns as opposed to how fast the first gear (driver gear) turns.

So you know how fast the first one is turning but now need a ratio of the two gears to find out how fast (or slow) the second gear is turning. Normally, to find the gear ratio, you'll divide the teeth count of the first gear (driver gear) by the teeth count of the second gear (driven gear). Example: A 20 teeth gear is driving a 40 teeth gear. By dividing the first gear teeth by the second gear teeth, you get a number of 0.5 (20 / 40 = 0.5). That means the second gear will only turn at a rate of 0.5 (or 1/2) turns when the first gear has made 1 full turn on it's shaft. And if the RPM of the first gear is turning at 1000 RPM, the second gear is turning at 500 RPM (1000 x 0.5 = 500).

The inverse of the gear ratio tells you how fast the first gear (driving gear) turns as opposed to how fast the second gear (driven gear) turns.

Now if you divide backwards instead, teeth count of the second gear divided by the teeth count of the first gear, you'll get a number that represents how much faster the first gear is turning as opposed to the second gear. So now the formula changes and you do the math to get (40 / 20 = 2). That means the first gear is turning 2 times when the second gear has made 1 full turn on it's shaft. And the speeds are the same between them. The RPM of the first gear is still turning at 1000 RPM and the second gear is still turning at 500 RPM (1000 / 2 = 500).

The inverse of the gear ratio also shows the torque ratio (or mechanical advantage) achieved by the certain gears paired together.

(which represents a change in torque or speed where the driven gear is either smaller or larger in teeth count than the driver gear and to what degree).

The power from the source “is what it is” and can only be changed by more or less throttle (or engine RPM). However, that power can be manipulated to either achieve more torque or more speed (but not both) further down the gear train by changing the gear ratios. The total power stays the same, from the conservation of energy (the law of conservation of energy says that energy is neither created nor destroyed. When people use energy, it doesn't disappear. Energy changes from one form of energy into another form of energy.) 2)

The mechanical advantage is a representation of leverage (or torque) gained or lost from gear ratios and is expressed in the form of a ratio.

These 2 different ratios above are generally not distinguished apart from each other or at least not enough.

As is shown, each result points to one or the other's gear speed although the result is to the relationship between both gears. The difference is in the calculations and which gear or gearset is being referred to.

Driver Gear vs Driven Gear

Determining which is which is crucial in calculating the gear ratio.

When the teeth are meshed together on the 2 separate shafts, one gear drives the other. The gear making the other move is called the driver gear and the other gear is being driven (thus driven gear). The driver gear is closest the power source. The power source is the engine by way of the engine sprocket (driver) which drives the mainshaft by way of the clutch sprocket (driven). The mainshaft receives power from the engine by way of the clutch. The clutch is between the engine and mainshaft and acts more like an on/off switch. With the clutch engaged, the mainshaft receives power from the engine. With the clutch dis-engaged, the mainshaft does not receive power from the engine. The mainshaft drives the countershaft in 1st-4th GEAR and the countershaft drives the M% and thus the transmission sprocket. And in 5th GEAR, the mainshaft drives M5 and thus the transmission sprocket, taking the countershaft out of the power flow.

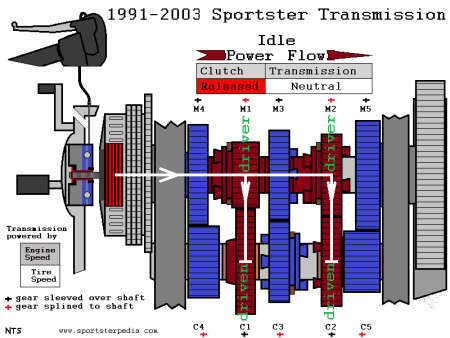

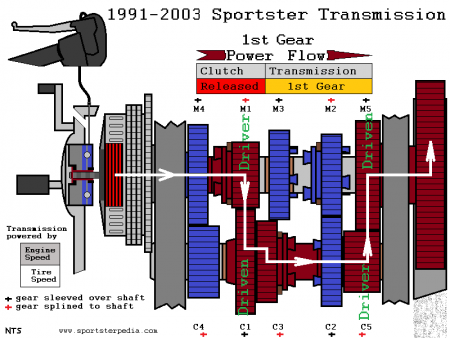

In the (left) drawing below, there are only 2 gears that are splined to the transmission mainshaft (M1 and M2 gears). The other 3 gears on the mainshaft are sleeved over bearings on the shaft and have to be locked to the mainshaft by way of either M1 or M3 in order to turn the shaft. There are '+' signs above/below each gear in RED or BLACK. Such as M4 has a BLACK '+' and C4 has a RED '+' and M1 has a RED '+'. The BLACK '+' gears are SLEEVED over the shaft on which they are located. This means they can turn separately from the shaft unless otherwise engaged. The RED '+' gears are SPLINED to the shaft on which they are located. This means they always turn whenever that shaft turns. Both M1 and M3 are sliding gears (as is C3) and they are moved by way of the shift forks when you move the shifter pedal.

M1 and M2 (in Neutral) are the driving gears and they are both driving their respective counter gears (C1 and C2). Neither C1 nor C2 are splined to the countershaft, they just sit there and spin while the transmission is in Neutral. So power stops there and allows the bike to idle without being “in GEAR”

In the (right) drawing below, M1 and M2 are still moving and turning their respective gears but now the power from the engine is being used to turn the engine sprocket (to rear tire) so the emphasis is on that flow of power. M1 is (driving) and C1 is being (driven). C1, being sleeved on the shaft, is locked to the countershaft by C3 which makes the countershaft turn. Following the flow of power,C5 is splined to the countershaft and turns when the shaft turns. However, the mainshaft 5th gear (M5) is sleeved and can't turn on it's own. With C5's teeth in constant mesh with M5, C5 is (driving) and M5 is being (driven).

M5 is splined to the transmission sprocket which turns when M5 turns. The transmission sprocket drives the rear wheel sprocket. 3)

Torque vs Speed

The gear ratio shows the trade-off between torque and speed. Speed is RPM and Torque is PUSH. 4) RPM is what is needed on the highway and Torque is the ability to move the bike faster from a stand still. Progressively through the upper gear changes, torque is lowered and speed is gained through gear ratio changes. As with the 2 gear train mentioned above;

If the driving gear is smaller than the driven gear, the result is the driven gear turns slower (less speed) but with (more torque) applied downstream of it.

If the driving gear is larger than the driven gear, the result is the driven gear turns faster (more speed) but with (less torque) downstream of it.

Example: A 20 teeth gear is driving a 40 teeth gear. The input speed is 1000 RPM and the input torque is 50 ft/lbs.

Using the gear ratio (20/40 = 0.5:1), the output speed was reduced to 500 RPM (1000 x 0.5 = 500).

Using the inverse gear ratio, (40/20 = 2:1) then multiplying the known input torque (50 ft/lbs) by the result, (50 x 2 = 100 ft/lbs).

So the output speed was cut in half by this gearset but the output torque doubled (this does not take into account efficiency loss).

However adding gear efficiency, ex. 99% for a spur gears, the formula changes to (40/20) x 50 x .99 = 99 ft/lbs of output torque.

The same mathing applies if the driver gear has more teeth than the driven gear. The results are just in reverse.

Formulas

- Gear Ratio for 2 gears = (number of teeth on driving gear) / (number of teeth on driven gear)

- Gear Ratio for 4 gears = (number of teeth on driving gear x number of teeth on driving gear) / (number of teeth on driven gear x number of teeth on driven gear)

- Inverse Gear Ratio for 2 gears: = (number of teeth on driven gear) / (number of teeth on driving gear)

- Inverse Gear Ratio for 4 gears: = (number of teeth on driven gear x number of teeth on driven gear) / (number of teeth on driving gear x number of teeth on driving gear)

- Output Speed = (input speed) x (gear ratio)

- Output Torque ratio for 2 gears = (number of teeth on driven gear / number of teeth on driving gear)

- Output Torque ratio for 4 gears = (number of teeth on driven gear x number of teeth on driven gear) / (number of teeth on driving gear x number of teeth on driving gear)

- Output Torque = (input torque) x (output torque ratio)