REF: Service Procedures 11D

What Causes the 1991-2003 Shift Drum Pins to Walk Out of the Drum

When you engage the shift pedal, the shift shaft is repositioned in it's bushings to the end of it's clearances (designed or constrained).

That begins the angle that the shift arm will turn. When the shift pawl grabs a pin, it pulls toward it's center axis at the shift arm.

That center axis is on a varying side to side angle. The shift arm rotates vertical to the shaft axis.

The shift pawl is also vertical to the arm but doesn't have a slide pivot at the arm. It simply has a designed lean from the flat plane.

The flat planed pawl is allowed to move fore and aft of the arm due to a loose clearance between the spacer washer and the pawl retaining ring.

In any up or down pull position of the pawl, the exact angle of pull will be different than the last pull.

The pawl is allowed to flail inward and outward on it's own by gravity until it is engaged to a pin.

The angle of pull on a pin can be rearward, centered or forward toward the left side of the bike.

The pawl hook grabs a pin and pulls up or pushes down in a rotating direction while changing the geometry of the shift shaft (angle of pull).

If the pawl angle exceeds the designed clearance at the arm, the connection at the arm stiffens and the pawl becomes a rigid extension of the shift shaft.

Shift drum endplay also has a roll in the angle of pull from the pawl also.

The pawl will pull the drum out or in (depending on the current drum position as opposed to the current pawl push/pull direction).

So when the pawl grabs a pin, it actually moves the shift drum sideways during that throw.

Shift fork and transmission gear movement will also move the drum sideways as will vibration.

In fact, you can stand the bike upright, slap the seat and the drum will move sideways.

The act of leaning into a curve will also move the drum (if it's not already moved in that direction to extreme end).

| Shift drum end play 1) |

|

There is plenty of clearance in the arm to pawl connection to allow the angle needed to keep the pawl from being pushed on the pin(s).

When the drum slides either way, the arm (should) stay in alignment based on it's varying constrained forces acting on it.

However, the pawl is designed with much clearance which allows compensation for changes in drum endplay and shaft play.

So the angle of the hooks and shaft arm should not affect the amount of torque or throw on a pin to complete a shift action.

Shift drum pins were not meant to move but due to quality control, construction, installation or quite possibly a combination of all of those, they do.

Heat and vibration are secondary contributors but without the heat, vibration will not pull a pin out.

If the shift arm / pawl turns outward during a shift, the drum is also pulled outward at the same time it is being pulled up or down.

Sometimes when the pawl is grabbing a pin and moving the drum, a pin will be in the right condition to be weak in it's pressed in tightness.

Normally, the pawl will pull the pin including the weight of the drum and any forces acting on it (shift forks and moving transmission gears).

However, if a pin's press fit gets weak enough, the pawl will pull the pin out of the drum instead (pin lets go of the drum).

The pin's press fit is weakened by heat. Vibration gives a weak pin joint a push and the pawl grabs and snatches the pin out.

If a drum pin is hot enough and subject to moving, the math is pretty easy from there.

When you see two or more pins that have moved, then that many pins were subject to be in that condition.

And they each individually let go when the condition was ripe (may or may not be consecutive shifts but won't be at the same time).

And they won't necessarily come out of the drum at the same lengths.

A momentary thrust from the quick act of a gear shift, then the shifter is dormant until the next shift is done.

Meanwhile, a pulled out pin then “sets” (cools) in it's new position and doesn't move any more until the next “perfect” condition is there to do so.

Due to shift drum endplay, a “shift ready” pin can technically be shifted outward or inward (L or R sitting on the bike).

So it is possible for a pin to pull out a few thousandths and later be pulled back in a few thousandths depending on the angle and condition at the time.

If the drum is already shifted forward and the force from the shift arm moves further forward, a pin not quite ready can go ahead and move.

The full weight of the pawl movement is on the pin at that point.

Due to design and / or construction, we can not change the fact that THE OEM PINS ARE SUBJECT TO MOVE OUTWARD.

And it can happen to any 91-03 Sportster.

The drum pins are not a full bodied press fit (the pin OD is smaller than the hole they go in).

The pins are spiked in a few places in circumference and the spikes create the interference to keep them in place.

(3 small bulges of metal protruding at the end of 3 small grooves in the middle of each pin)

These small bulges are not enough to keep the pins in place during extreme conditions.

But they are forgiving enough to keep them midway in their holes after protruding, creating that side force on the detent plate.

If the pins were a full body press, they probably wouldn't pull out so easy.

But then again, one has to ask if it's poor pin construction or thermal expansion of the shift drum holes.

However, if it was the drum getting too hot, all the pins would be subject to walking out.

| Example of pins pulled out on of xLoneRiderx's shift drum. See the spikes in the side of the pin that create the interference fit in the hole. 2) |

|

|  |

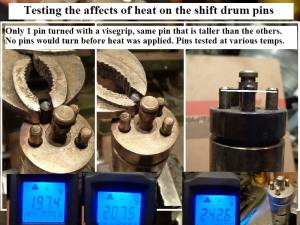

Heat testing was done on the shift drum pins below.

In the third pic below, heat was applied to the old shift drum to find what operating temps may be when a pin pulls out.

At ambient temp, none of the pins would turn or move being clamped in vicegrips.

The drum was clamped in a vise, heat applied to it with a propane torch and the heat from the drum was measured with an infrared thermometer.

At various temps (197°F, 207°F and 242°F), all the pins were clamped with an attempt to turn them and only 1 of them ever moved.

Coincidently, it was the same pin that had previously been found to have pulled out from the it's bore making the detent plate skew.

Anywhere before and after the 200° mark, the one pin could be turned.

So that is the heat range where that certain pin will no longer hold.

The other three pins took 242°F but did not move. So it appears it's not just heat that makes the pins move.

It's a combination of heat, pin fit, vibration and how much of a pull or thrust the shift pawl gives outward that makes the pin(s) walk out.

Some press fits are tighter than others especially if speaking of how tight the spikes on the side of the pins are.

Either some of the spikes (or bulges) are made taller on some pins than others or they get squashed more than others by the original installation.

So it appears it's construction, installation or a more probable combination of both that leaves some pins looser than others (but still a press fit).

| Heat testing the pins 3) |

|

Some have tossed around ideas on redesigning the pins and / or the spring clip that holds the detent plate to the drum.

One idea is to weld the pins to the drum.

However, the load is going to happen any way due to construction and clearances up stream of the pawl (and pin movement is actually a symptom and not a cause).