Table of Contents

IH: Oiling & Lubrication - Sub-01Q

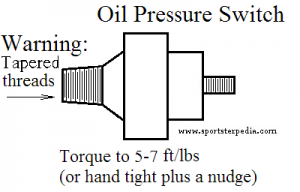

Oil Pressure Switch Removal and Installation

Installation

Caution: DO NOT tighten the oil pressure switch too tight.

It will either strip the threads in the filter housing or crack the filter housing.

If you don't have access to a torque wrench or can't get one to fit in there, use a “hand tight plus a little” approach when tightening the switch.

You can also clamp a nut in a vise if needed, install a bolt and tighten it to 5-7 ft/lbs.

Then use a open/box end wrench to feel the point where it turns.

Then you have a bench mark 'feel' for how tight to turn the pressure switch with the same type wrench.

This one got tightened too much and cracked the filter housing.

Don't over tighten to try and stop a leak. It doesn't take much oomph to seal the pressure switch.

Don't use silicone on the threads. Thread tape may break off and enter the filter or the engine.

In theory, you should be able to stop a leak from the switch threads without any thread sealer because of the tapered threads.

But thread sealer of some type (Loctite, plumbing pipe dope or other) is suggested.

Keep in mind that any thread dressing applied will pre-load the torque needed.

So be sure to back down on final torque when using thread sealants.