Table of Contents

EVO: Suspension - Sub-01D

1200S Fork Rebuild & Hyperpro Spring Fitment

Article and Pictures by steelworker 1)

- The 1200S forks seem to be somewhat sought after, as the only fully adjustable forks ever fitted to a sporty in these year models. They are pretty good, but I always thought they could be better (a bit harsh over smaller bumps, and a lot of dive under hard braking), so I bought a set of Hyperpro progressive springs. The fitment will follow the same procedure as a full strip and overhaul,

Click on a pic to enlarge:

PART 1: The Parts

| When I was finished, I ended up with three O rings left over from the kit for each leg - the two tiniest ones, and the largest diameter ring. The two small rings I guess are for the shafts of the two damper adjuster knobs, but, since the knurled knobs appear to be located using tiny roll pins (which I don't have a replacement for), I left these well alone! The largest O ring appears to be larger in diameter than anything else on the forks! I saw nothing like it, I have no idea what it's intended for, and I'm not going to lose any sleep worrying about it. |

Part 2: Special Tools You'll Need

- Firstly, a fork spring compressor, and a slotted plate (Lower Left Pic)to retain the spring while you remove the top nut and preload adjuster. This homemade compressor is made from 50mm diameter pipe (this is 2.5mm wall thickness, but thicker would be better), 30mm long, drilled and tapped to take a couple of M6 bolts. The slot cut out of the wall is approx. 28mm across. A thicker wall and larger diameter bolts would be better, but this tool did the job admirably. Wear leather gloves when using the tool to prevent pinching that particularly sensitive piece of flesh between your thumb and forefinger!

- The slotted plate is 55mm x 35mm, with a 12mm wide x 33mm slot. For the sporty, a slighty narrower slot would be better / safer. It has to fit around a 10mm rod, so make it as close to 10mm as possible.

- The only other special tool you'll need is a fork oil level dipstick. We made one out of a gigantic zip tie. From the underside of the head, mark the tie at the recommended oil level (150mm for Hyperpro; 144mm Stock), then trim the tie about 100mm below the mark. This will enable you to slowly add oil and see when the level is approaching the mark. We looped a smaller zip tie through the head of the “dipstick” to prevent any “Oh , where did that go?” moments further down the line.

- Apart from these expensive special tools, the only other oddity you're likely to need is a long 8mm allen socket for the fork bottom screw (the one which bolts the damper rod to the bottom of the fork slider). Or do as we did, and use a cut down old 8mm allen key and use with an 8mm socket.

- A copy of the factory manual is invaluable when doing anything like this. Apart from the illustrations and instructions, it gives torque settings for a number of items - top nut to damper rod, top nut to stanchion, and bottom damper bolt.

Part 3: Remove The Forks

- First, loosen the front brake caliper bolts and remove the front fender. Loosen the front axle nut, and the pinch bolt on the other side.

- Now we have to get the bike off the deck. If you have a bike lift, that's fine. I don't, so a little trick is called for, as taught me by my mate Sparkin':

| You can now crack the top nut. I had a socket that fit, but a ring spanner (or even an adjustable wrench) would do the job. Just loosen it - do not remove it fully yet. |

|

- With the fork still supported, now is a good time to crack the bolt in the bottom of the forks (the one you cut down the 8mm allen key to fit). It has a very shallow head, so be sure you have the allen key pushed well into it to avoid rounding it off and suffering the pain that would surely follow.

- You can now loosen the bottom yoke pinch bolt and drop the stanchion out and put it to one side.

Part 4: Dismantle The Forks

- It's best to do this one leg at a time to keep down confusion

- Before you start, back off all the adjusters (preload, compression and rebound) to their minimum settings.

- Now the stanchion is off the bike, you can fully undo the top nut. For those with experience of fork top nuts, under massive spring pressure, stripping the last few threads as they are propelled upwards to embed themselves in your forehead or garage roof, you're in for a pleasant surprise; because this doesn't happen with 1200S forks! As you're undoing the nut, support the stanchion, which will now drop down into the fork slider, revealing the rebound adjuster assembly and spring.

- Now we have to use the spring compressor again. Note that the “handles” should be only just inside the holes - too far and they will foul the damper assembly as you release spring pressure. It helps if you can turn the spring space so the holes line up with the flats on the damper above, to give a bit more clearance.

- With your assistant pressing down on the spring, hold the top of the damper rod and remove the slotted plate. Your assistant should now gradually let the spring up, while you guide the spring spacer / washers / spring past the damper (mind your fingers!).

- Remove the spacer and washers, then pull the spring out of the fork.

| Now you can see the dust cover | Remove that in similar fashion | Now you can see the fork seal and retaining ring, covered in 12 years worth of road grime that the dust cover didn't keep out. |

|  |  |

Part 5: Replace the O-Rings

| Pull the preload adjuster out of the top nut. | To reveal…Replace the large diameter O rings on the outside of the preload adjuster and top nut. |

|

|  |  |

Part 6: Reassemble Fork Tube

- There is no way to hold the damper tube in place as you tighten the bolt (20-29 ft-lbs), which is not a great thing. The bolt in one of my fork legs did torque to 25 ft-lbs, but the most we could get on the other one was about 10ft-lbs before the damper tube started spinning (even after fitting the spring and compressing the fork to put some pressure on it).

- This may be a function of the shorter Hyperpro springs with lighter initial spring pressure.

- Next, we have to fill the fork with oil. The stanchion has to be fully bottomed in the slider whilst doing this, and the fork leg held vertically. Again, we clamped a caliper boss in the vice to hold it steady.

- When you've reached the correct oil level, it's time to install the spring. You'll need a second pair of hands again for this operation.

- Feed a piece of string through the spring, and loop it around the rebound adjuster knob. This will allow you to raise the damper rod as you install the spring.

| Fit the spring WITH THE TIGHTER WINDINGS TOWARDS THE TOP. Feed it s-l-o-w-l-y into the fork tube, and raise the damper rod above it. |

|

- Slide the spring spacer, with a washer either side of it, over the damper tube. Whilst you hold the damper rod up, get your assistant to compress the spring, until you can again fit the slotted plate beneath the steel lock nut under the damper assembly.

- Now get your assistant to compress the spring again, while you remove the slotted plate, then slowly release the spring pressure as you guide the spring spacer and washers into place below the top nut.

- With the top nut in place, raise the fork stanchion to the nut and screw the nut into the fork tube.

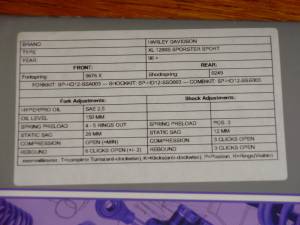

- Adjust the preload, compression and rebound adjusters to Hyperpro recommendations:

- Spring Preload: 4-5 turns out.

- Compression: open (minimum)

- Rebound: 6 clicks open (+/- 2)

- These are starting positions. The Hyperpro booklet contains detailed instructions for suspension set-up, which I won't go into here.