Table of Contents

EVO: Oiling & Lubrication

Oil Pump Unit

Sub-Documents

- 86-90 Sportster Oil Pump:

- 91-96 Sportster Oil Pump:

- 97 Sportster Oil Pump:

- 98-06 Sportster Oil Pump:

- 07-Up Sportster Oil Pump:

- 07 Buell Oil Pump:

- Oil Pump Comparisons:

- Oil Pump Conversion:

Note: Be sure to check the REFERENCE section for additional information related to Oiling, Lubrication and Mods.

Oil Pump Fittings and Oil Paths

Different year oil pumps came with several different fittings. Part numbers and usage is labeled in the pics below.

Note: HD fittings are generally beefier than aftermarket fittings (especially from your local hardware store).

Some of these fitting started out in the ironhead or pre-ironhead days in metal or brass construction.

HD later replaced some metal fittings with brass using the same part number.

You can find some in NOS condition in metal as well as brass or zinc.

Colony sells some in cad plated versions and you can also find some in chrome online.

Note:

Fittings 26496-75 and 26496-75A are the same fitting accept the -75A version comes with lockpatch on the threads.

Fittings 63533-41 and 63533-41A are the same fitting accept the -41A version comes with lockpatch on the threads.

Fittings 62601-91 and 62601-91A are the same fitting accept the -91A version comes with lockpatch on the threads.

- 1986-1990 oil pumps feed oil to the motor from the top side of the pump.

Feed oil goes from oil tank to the lower gerotors, out the lower feed fitting to the filter pad, back into the pump through the middle (upper feed) fitting.

Return oil drops into the “duck bill” on the back of the pump, to the upper gerotors to the top “dual” fitting, to the tank. - 1991-1997 oil pumps feed oil to the oil filter pad (actually 1991-present Sportster oil pumps do).

Oil is sent from the filter into the motor by another oil passage machined into the right engine case.

Feed oil goes from the oil tank to the lower gerotors, out the lower front fitting to the filter.

Return oil drops into the “duck bill” on the back of the pump, to the upper gerotors, to the upper front fitting, to the tank. - 1998-Up oil pumps also feed oil to the oil filter pad, with the (routing) difference being an added return inlet in the top of the pump.

Feed oil goes from the oil tank to the lower gerotors, out the lower front fitting to the filter.

Crankcase return oil drops into the “duck bill” on the back of the pump, to the upper gerotors, to the upper front fitting, to the tank.

Cam chest return oil drops into the extra inlet in the top front of the pump, to the upper gerotors, to the upper front fitting, to the tank.

Click Here to reference the Oil Tank, Lines and Routing Page in the Sportsterpedia.

Oil Pump - Complete Unit Part Numbers

1986-1990 Models - XL P/N = 26204-86

- pump body catalog p/n 26484-86

- pump body casting p/n 26485-

… casting p/n is in return cavity

… also has a “2” stamped next to casting #

… also has a “T” stamped into opposite return cavity

- bottom cover catalog p/n 26486-86

- bottom cover casting p/n 26487-86

1991-1996 Models - XL P/N = 26204-91

- pump body casting p/n in 26485-90

… casting p/n is in the return cavity

… also has casting #s 1 and 380 in opposite return cavity

- pump cover casting p/n 26487-90

… casting p/n is on the outside of the cover

1997 Models - XL P/N = 26204-91

- pump body casting p/n in 26485-90A

… casting p/n is in the return cavity

- pump cover casting p/n 26487-90A

… casting p/n is on the outside of the cover

1998-1999 Models - XL P/N = 26204-98

- From the internal P/N changes it appears that this new

… P/N was generated because of a change in the

… Gear Shaft and Gerotor Return set of gears

- has body casting P/N 26487-98 in the return cavity

- has bottom cover casting P/N 26487-98 on the outside

2000-2006 Models - XL P/N = 26204-91A

- P/N change appears to be related to fitting changes

… feed inlet and outlet have -A suffix but no change in fitting size

- has bottom cover casting P/N 26487-98

2007-later Models - XL P/N = 26204-91A (new design)

- is a different design w/same P/N (How crazy is that?)

- is retrofitable to 1991-2006

- has body casting P/N 26211-07 in the return cavity

- has bottom cover casting P/N 26213-07 on the outside

Buell P/N - 26357-02B

- same pump as XL 26204-91A (new design) but with different fittings

- will bolt up but you need to change the fittings over to XL style

- has bottom cover casting P/N 26213-07

Buell P/N - 26357-02

- Same pump as 1998-1999 XL 26204-98 but with different fittings

… same gerotors, same cover casting number

See these XLForum threads:

https://www.xlforum.net/forum/sportster-motorcycle-forum/sportster-motorcycle-motor-engine/sportster-motorcycle-bottom-end/43858-evo-sportster-engine-oil-pump-up-date?t=135265

https://www.xlforum.net/forum/sportster-motorcycle-forum/sportster-motorcycle-era-specific-and-model-specific/rubber-mount-sportster-motorcycle-talk-2004-2006/161897-which-oil-pump-buell-26357-02b-or-xl-2007-26204-91a?t=1738158

Oil Pump Function

The oil pump is a positive displacement unit.

If you block the discharge flow path, discharge pressure will rise and literally approaches infinity until something fails. 6)

It's non-regulated and delivers its entire volume of oil under pressure to the oil filter mount.

However, don't take the term “positive displacement pump” literally. 7)

Compared to a centrifigal pump, gear / gerotor type pumps use displacement to function.

How positive it is depends on what it's pumping.

The most 'positive' pump on our bikes may be the master cyl for the disc brakes.

You pull the lever and it pumps real good, positive, unless there is air in the system.

Then you still get the displacement but not the pressure because liquid is not compressable but air is.

Gear / gerotor type pumps work by filling the spaces between the teeth with whatever it is that is being pumped (oil in our case).

The oil in the tooth spaces gets squezed out of the spaces when the gear teeth mesh together (because a tooth is now in that space.

But there is still a little space left at full mesh.

Gearotor pumps have a smaller space at full mesh than gear pumps.

Now when the mesh breaks, a void is created. Oil gets sucked into that void.

Now what if air is in the spaces instead of oil?

It gets sqeezed out also unless there is pressure (restriction) in the curcuit its trying to flow into.

In that case, some air stays in the spaces and gets compressed in the small space remaining as the teeth mesh.

When the teeth unmesh, air expands (refilling void that should be getting oil sucked into it.

The pump can't make enough pressure to overcome the exit restriction.

Then there is no flow and no ability to reprime itself since.

(it's not making enough suction due to the expansion of the compressed air refilling the void that the oil should be filling)

Eventually the pressure in the return line gets released.

While this is happening oil is building up in the pickup sump and waiting for the return side to come back online.

The supply pump is still pumping while the return is toggling from air locked to primed and pumping.

Think about what state the return oil is in as it collects in the return pickup cavity. It's just been thru a 60 cycle blender.

Our bikes live with that every mile they travel with lots of air whipped into every drop of return oil.

Restrictions in the return side of the pump will lead to a more sustained oil level in the crankcase sump.

(large enough to reduce outflow from the engine to a volume less than the supply pump is feeding the engine)

This is a condition known as wetsumping.

Read more about wetsumping in the REF section of the Sportsterpedia.

| Typical 98-up gerotor positioning over the pickup cavities (07 pump shown). 8) | |

|  |

Oil Pump RPM

There are 10 teeth on the drive gear at the pinion shaft and 20 teeth on the oil pump driveshaft.

This creates a 2:1 ratio of the gears (20/10 = 2:1) meaning the oil pump RPM is half the speed of the engine.

(running at 4,000 RPM, the oil pump is turning at 2,000 RPM)

Oil Pump Pressure (86-Up)

See also Installing an Oil Pressure Gauge in the REF section of the Sportsterpedia.

Engine oil pressure was measured (by the MoCo) with a pressure gauge at the oil pump.

Expected oil pump pressure per FSM's:

Gauge mounted at tappet hole plug

As checked with hot oil and a gauge at the plug hole on the engine case between the tappets.

The plug between the tappets has to be removed for the gauge to be installed.

1986-1990: 9) 10)

Minimum: 1-7 psi (idle)

Normal riding conditions: 5-30 psi (2500 rpm)

1991: 11)

Minimum: 7-12 psi (idle)

Normal riding conditions: 12-17 psi (2500 rpm)

1986-1991 models have a high pressure regulator built into the feed path to dump excess pressure to the bottom of the cam chest.

The relief valve pressure is 30-35 PSI so any oil in that pressure range does not go to lubricating or cooling the motor.

It's just dumped to drain back into the return path to the tank.

Click Here to read more on the oil pressure regulator in the Sportsterpedia.

1992-Up cases ditched the pressure relief valve and got a small hole drilled into the upper cam case thru the oil feed path.

That hole serves as a pressure relief as well as an extra spray of oil to #2 cam gear teeth.

So 1992-up models have a constant pressure release in a way.

Click Here to read more on in the Sportsterpedia.

Gauge mounted at oil filter pad

As checked with hot oil and a gauge at the oil pressure switch location at oil filter pad.

The oil pressure switch has to be removed for the gauge to be installed.

1986-1990: 12)

Oil pressure, when checked at the oil filter pad (oil pressure switch removed), will be 6-10 psi higher than when checked at the tappet plug on the case at idle.

See pressure figures above when checked at the tappet plug hole.

1992-2004: 13) 14) 15) 16) 17) 18) 19)

Minimum: 7-12 psi (idle speed varies from 950-1050 rpm between the different FSMs)

Normal riding conditions: 10-17 psi (2500 rpm)

2013 XR1200X: 20)

Minimum: 16-20 psi (idle)

Normal riding conditions: 40-44 psi (2500 rpm)

Oil pressure relief (50 psi)

- It includes an oil cooler with a thermostat that starts to open at 190ºF (88ºC).

- The oil pump and the head breathers are a new design.

The oil pump rotors are driven by the cams, the feed rotor is driven off the front intake cam and the scavenge rotor is driven by the rear exhaust cam.

Oil Pump Volume (1977-Up)

It is not stated in the manuals how much oil these pumps will deliver.

However, testing has been done to find out the flow rates (both feed and return sides) on 1977-up gerotor pumps.

See the links below for those articles in the Sportsterpedia.

- Measuring Output Volume (flow rate) of a Gerotor Oil Pump: Measuring by flow rate by cc'ing gerotors as well as bench testing in real time.

Oil pressure has a direct relationship with oil flow rate.

Oil pressure also changes throughout the feed path. The most pressure will always be at the oil pump.

Oil pressure is reduced as oil travels though the restrictions in the engine.

The manuals state the oil pump will deliver it's entire content under pressure.

And that is true, with exception. The oil pressure under normal riding conditions is generally low.

As RPM goes up, the oil flow goes up and the pressure in the feed path goes up.

As RPM goes down, the oil flow goes down and the pressure in the feed path goes down.

The caveat is the outlet sizes (restrictions) in the oil feed path.

The outlets are very small orifices (crankpin and rockers).

Add the #2 cam squirter on 1992-up engines and the 2 piston squirters on 2004-up engines.

As RPM goes up, flow increases and the outlets get flooded with more oil pushing thru them.

If oil can't get thru outlets as fast as pump is pushing the oil, pressure rises on the incoming side of outlets.

Faster flow thru the outlets = less pressure in the feed path, slower flow thru the feed paths = more pressure in the feed path.

This is why pressure is always highest on cold startup and pressure falls as the oil heats up.

Colder oil is thicker and more resistant to flow. Hotter oil is thinner less resistant to flow.

Priming the Oil Pump

A dry pump won't pump oil.

It will 'cavitate' when their is not a hydraulic seal between the gerotors and the inlet hose from the tank.

Any time you have removed the oil pump or the removed / drained the feed hose from the oil tank, the pump needs to be primed.

- The oil pump needs to be primed with oil / lube before it can transfer oil from the inlet to the outlet cavity inside.

- Prime the oil pump per the FSM;

- Upon removal / inspection, oil the pump internals.

- Remove the oil pressure switch and rotate the engine until oil comes out the end of the pump and reinstall the switch.

- If you let it sit long enough, oil will gravity drain inside the pump and prime it.

- Another way to prime the pump is to use assembly lube on the gerotors and inside of the pump before installing it. 21)

Then you have an instant hydraulic seal to help the oil pump suck oil from the hose. - You can also using a large syringe with a tapered tip inserted into the oil supply hose on the bottom of the oil tank. 22)

Then you can force feed oil to the pump and on to the engine using this technique.

Oil Pump Gaskets / Seals

Note: all 1977-present Sportster oil pump to engine mounting gaskets have app the same bolt pattern holes.

The main difference is 1977-1990 gaskets are longer to match their longer snout oil pumps (these can be cut down to fit 91-up pumps).

All 1991-present pump to engine case gaskets will interchange without alterations.

|

|||

|---|---|---|---|

| Year Model | Part# | Notes | Pics |

| 1977-1990 Sportster | 26495-75 | Oil pump to engine case mounting gasket | Pic 23) |

| 1977-1990 Sportster | 26434-76A | Pump cover to body O-ring seal Can also use part #26434-76 | Pic 24) |

| 1983-1990 Sportster | 12036A | Shaft oil seal between divider plates. Use only with outer plate 26493-75A | Pic 25) |

| 1991-1993 Sportster | 26495-89 | Oil pump to engine case mounting gasket All 3 gaskets will interchange in the case of finding a NOS gasket | |

| 1994-2003 Sportster | 26495-89A | Pic 26) | |

| 2004-Present Sportster | 26495-89B | ||

| 1991-Present Sportster | 26434-91 | Pump cover to body O-ring seal | Pic 27) |

Leaky gaskets and hose connections

Internal leaks

Generally, oil will leak into the motor on shutdown (especially on extended shutdown periods).

For more information on that, Click Here to view “Sit Sumping” in the REF section of the Sportsterpedia.

Below is concerning an issue with gaskets or seals where either oil / air or both leak into the motor while riding.

Oil Pump Date Code

91 and Up Oil Pumps

The casting date code is in a circle on the mounting surface near the return fitting.

A 'year of manufacture' number is stamped inside the circle with 12 hash marks around the circle.

Dots are cast around the hash marks to represent the month of manufacture.

Count the dots, add the year and you have the month and year of manufacture for that particular oil pump.

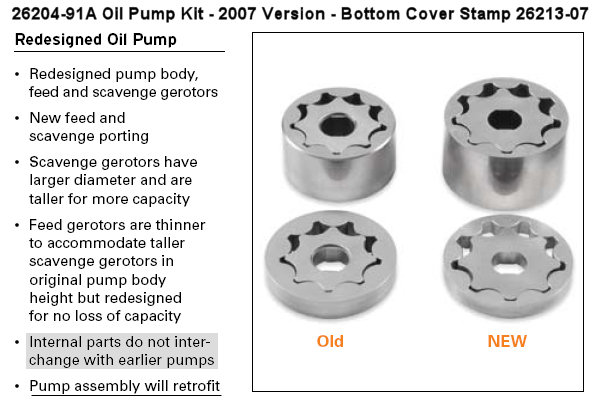

Oil Pump Upgrade 26204-91A

- In addition to the upgraded Drive Gear (26391-06), there is also an upgraded entire Oil Pump (first installed on 07-later Sportsters). The new pump reuses the same full unit part number as a previous version, making it difficult & confusing to know to which version someone is referring. The old (& new) part number for the complete oil pump unit is 26204-91A (that P/N first showed up in model year 2000 and used for the older design thru model year 2006).

- The difference between the 1998-2006 version and the 2007-later version relates to the drive shaft, internal Gerotor return & feed gears and the body (which cannot be ordered separately). The internal parts for the new pump design are not backward compatible to the 98-06 pump design.

- The only known external indicator to identify that the 2007 pump version (using P/N 26204-91A) is currently installed is the cover casting number 26213-07 which is stamped on the bottom of the new version.

- The upgraded pump is compatible (and recommended) for use on 1991-later Sportsters.

However, it is not the answer to wetsumping (which involves more than just the pump).

Here are the internal servicing part numbers from 1998-2000 version and 2007-later version:

| Part Name | 1998 P/N | 2007 P/N |

| Gear Shaft | 26488-98 | 26239-07 |

| Gerotor Return Set | 26491-98 | 26502-07 |

| Gerotor Feed Set | 26492-91 | 26503-07 |

| Separator Plate | 26493-91 | Unknown? |

| Bottom Gasket | 26495-89A | 26495-89B |

2007 XL and Buell Oil Pump Comparison

- 2007 XB engines got a new up-dated oil pump which will retro fit to older EVO Sportster Engines, BLAST engines and older XB Engines … 33)

- The -07 XB oil pump is part number 26357-02b. The 07 part number seen on the housing is simply just for the lower housing. 34)

- The part number for a 2006 is 26357-02A. 35)

- The -07 Sportster pump changed at the same time and got the same improvements and the only reason the part number is different from the Buell pump is that the fittings are different. And what's more, just a brief look at some parts books shows that the part number for all Sportster pumps from 2000 to thru 2007 + is the same (26204-91A). So they changed the pump in 2007 as Buell did. However, it doesn't appear that they changed the part number. So with the 07-up XL style oil pump, even though the pump’s part number didn’t change from the 2000 model year, the gerotor part numbers did.

- Both the Sportster 2007 Oil Pump (26204-91A) and Buell 2007 Oil Pump (26357-02B) have gerotors with the following same part numbers:

- Feed — 26503-07 GEROTOR SET

- Return - 26502-07 GEROTOR SET

- So, it does appear that the Sportster got the same oil pump improvements. Why they changed the Buell pump part number in '07, and yet didn't change the Sportster pump part number at the same time, I have no idea. Just to confuse us I guess. 36)

- The Sportster pump #26204-91A and the Buell pump # 26357-02B are the same 37)

- The only difference in the pumps are the fittings that come installed on the pump 38) which can be removed and replaced with the fittings that you need for your XL.

Oil Pump Drive Gear

88 and up:

A material change to cast iron for increased service life was implemented on April 23, 1992. 39)

The new gear has a part number change to 26318-88A. This part will retrofit to all Sportster models, 1988 and later.

Below is a used gear that does show some wear.

40)

40) 41)

41)

Dims are also from this used gear. 42)

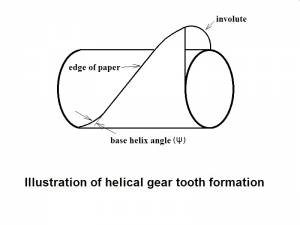

Gear Configuration

The gear mesh (oil pump driveshaft gear to drive gear on the pinion shaft) looks to be a worm gear configuration.

However, that is not accurate. It's actually two right handed helical gears in a 90 degree configuration (or cross axis helical gears).

The teeth on these gears stay in contact longer than straight teeth spur gears. 43)

(which allows them to transmit higher loads at higher speeds than spur gears)

The gears are carbon steel for strength with hardened teeth for increased wear resistance.

(once axial play wears the hardness, the teeth wear down rather quickly)

For the gears to mesh correctly, they must have the same pressure angle and pitch.

Helical gears can be configured to transmit motion in a straight line (or used for Sporty oil pumps at a 90° angle).

To transmit motion at a 90° angle, 2 gears are paired in the same tooth direction (right handed).

1977-1987 Oil Pump Drive Gear

The 1977-1987 pinion shaft has 6 external splines all being the same length.

The 1977-1987 oil pump drive gear (26318-75) has 6 internal splines that match to the pinion shaft and is a slip fit over the shaft.

The drive gear slides onto the pinion shaft with no direct radial or front to back positioning and has no timing mark.

So you can install the drive gear in any position where it will fit on the shaft (has no front or back either).

| 1977-1987 Sportster Oil Pump Drive Gear 44) | ||

|  |  |

Drive Gear Removal

The drive gear is inside the gearcase and the cover will need to be removed to access the gear.

See Removing the cam cover in the Sportsterpedia.

With the cover off, you'll need a tool to lock the pinion gear to remove the nut that holds the assembly together.

Once the pinion gear is removed, the pump drive gear slides off the pinion shaft.

Known Drive Gear Failure

Inspect your oil pump drive gear especially if you've gotten your gearcase cover off anyway to hopefully prevent gear failure before it happens.

- Generally speaking, the stock (drive gear) is fine for stock power levels and rpm's. Sure, there are some failures on stock or near stock bikes, but it's pretty rare. 45)

Of course, they do eventually wear down and should be replaced with the upgraded version. And if something gets into the pump and locks it up, the teeth get ripped off the gear. 46) - The failure happens because of pinion shaft runout (especially when the power level is raised).

This causes the engagement depth of the teeth to change as the pinion shaft rotates.

This causes the teeth of the steel oil pump drive gear to wear badly on one side.

You'll see the teeth getting real sharp there.

Generally, 180° from the worn teeth (front of tooth pitch) you'll see almost no wear at all so you have to inspect all the way around the gear (rear tooth pitch). 49)

- So lots of people get fooled when they check the gear. They'll look at the visible portion from their vantage point only.

You have to look all the way around the gear though. The wear will be isolated to one area only. 50) - With the gearcase on, you may be able to pull the oil pump and look up inside, and inspect the gear while slowly turning the motor. 51)

- You may still want to remove the cover, pinion nut and gear to get a good prospective on the health of the drive gear. The damage can be easily overlooked.

It usually happens on one side of the teeth on the gear due to pinion shaft runout forcing the gear outward while it is moving against the rigid mounted oil pump gear. - If you see the teeth sharpening, you're on borrowed time.

When one of these steel gears fails, it's really ugly and makes a mess and can damage a lot of other things as well.

- The bronze gear solves the problem nicely though. It's a Buell piece that came out in 2006. This was a much worse problem on Buells due to the higher power levels.

But at 65hp, it's not nearly so big of an issue, so HD never bothered to put them in XL's probably due to cost.

It's a good upgrade when hopping up an XL and it's cheap insurance against a catastrophic failure.

- Concerns of the carnage if the gear shrapnels:

- Debris locking up the oil pump.

- Scoring the oil pump cylinder, feed and scavenge gears which opens up the tolerances keeping it from pumping oil correctly in the future.

- The debris is also exposed to (everywhere oils travels) as in all the inboard cam bushings 54), rings, cylinders, rockers etc. so it can be catastrophic failure depending on the severity of the initial damage.

- Cleanup upon discovering broken / exploded metal parts anywhere in the engine:

- Simple answer, check and clean everywhere oil can travel. Choosing not to has proven to be destructive to the engine.

- You can run a magnet along most non-confined areas to check and remove metal particles.

| Oil pump and drive gear damage. 55) | |

|  |

| More oil pump and drive gear damage 56) | |

|  |

A chunk of a tooth from the oil pump gear fell out of the oil pump upon dis-assembly 57)

A chunk of a tooth from the oil pump gear fell out of the oil pump upon dis-assembly 57)

Bronze Oil Pump Drive Gear Upgrade (26391-06)

- This upgrade is compatible with 1991-later models.

- HD finally came out with an upgraded drive gear in 2006 for the Buell models to solve the high-rpm wear problem. Pinion shaft runout was the cause and occurs mostly because of high rpm operation causing flywheel spread. This failure has always been a terrible issue with Buells as they had higher rev limits from the factory - 6800 for most tubers and up to 7500 for the XB9. Even bone stock Buells were having this failure.

- But the MoCo never bothered to put it in XL's. It probably costs more than the steel gear, and given that failures are rare at 60hp, it just wasn't needed. But if you're hopping up an XL, it's a good piece of insurance. Especially if you're going into the cam box for a cam swap anyway, then it's a no-brainer in my opinion. It's a really ugly failure that generally requires a full tear down to fix. The gear is an ounce of prevention. 58)

- The bronze gear doesn't have this issue because of the different wear characteristics of the metal. The oil pump drive gear sees a lot of sliding friction, which causes the steel on steel to wear quickly. Bronze has much less friction than the OEM gear. The bronze gear is also uniform throughout, and thus it wears more predictably. So even if bronze is softer than steel, all of the factors in this application end up giving it a longer life than the steel gear. 59)

- It's cheap insurance, even if you only plan to visit 7,000 RPM instead of living there. 60)

- The upgraded Bronze Oil Pump Drive Gear is P/N 26391-06. This upgraded drive gear is compatible with 1991-later Sportsters using either the stock oil pump or the 07-later oil pump. Check your local HD dealer for availability (even though the part number is now obsolete from HD, there may still be one on the shelf somewhere) or you can buy it here.

- You'll need a tool to lock the pinion gear to remove the nut holding the assembly together. Using this tool is critical - do not remove or install the nut without a locking tool!

- The factory torque spec for the pinion gear nut is 35-45 ft/lbs.

This torque value reportedly is too low to hold the pinion gear in place while using high pressure valve springs.

Industry machinists recommended torque value should be 70 ft/lbs. and then using red Loctite on the threads (as in the FSM). 63) - Lock the pinion shaft on the pinion side before torqueing the nut.

- Holding the flywheel still by any method on the other side of the flywheel assembly will allow the torque applied to the nut to be transmitted through the flywheel assembly, putting it at great risk of being knocked out of true, which requires a full tear-down to fix. 64)

Related Links

History and installation video of the bronze oil pump gear from Hammer Performance