Table of Contents

EVO: Carburetor, Intake Manifold & Exhaust

Exhaust

- 1998 Swiss model Sportsters were equipped with catalytic converters. 1)

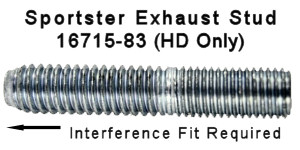

Studs

“Use the factory studs - They're the only ones out there

with interference fit threads on the head side. 2)

Gaskets

The Exhaust Port Gasket is a crushable gasket intended to seal the opening between the cylinder head exhaust port and the upper end of the exhaust pipe. In most cases, it is best to install it into the exhaust port and then align the pipe to it. Tighten the exhaust pipe flange nuts in alternating steps so that the pipe draws to the head evenly.

There are a number of XLForum threads regarding installing the Exhaust Port Gaskets.

https://www.xlforum.net/forum/sportster-motorcycle-forum/sportster-motorcycle-intake-and-exhaust/sportster-motorcycle-air-intake-carburetor-efi-fuel-and-exhaust/26591-exhaust-gaskets-are-new-ones-needed-everytime?t=44022

https://www.xlforum.net/forum/sportster-motorcycle-forum/sportster-motorcycle-intake-and-exhaust/sportster-motorcycle-air-intake-carburetor-efi-fuel-and-exhaust/44394-exhaust-port-gasket-help?t=143646

https://www.xlforum.net/forum/sportster-motorcycle-forum/sportster-motorcycle-motor-engine/sportster-motorcycle-motor-top-end/49878-cometic-gaskets?t=204486

https://www.xlforum.net/forum/sportster-motorcycle-forum/sportster-motorcycle-intake-and-exhaust/sportster-motorcycle-air-intake-carburetor-efi-fuel-and-exhaust/99840-exhaust-gaskets?t=856566

https://www.xlforum.net/forum/sportster-motorcycle-forum/sportster-motorcycle-intake-and-exhaust/sportster-motorcycle-air-intake-carburetor-efi-fuel-and-exhaust/146979-se-exhaust-gaskets?t=1597528

https://www.xlforum.net/forum/sportster-motorcycle-forum/sportster-motorcycle-intake-and-exhaust/sportster-motorcycle-air-intake-carburetor-efi-fuel-and-exhaust/165416-se-exhaust-gaskets-are-junk?t=1779860

Here are some comments from this thread: (https://www.xlforum.net/forum/sportster-motorcycle-forum/sportster-motorcycle-intake-and-exhaust/sportster-motorcycle-air-intake-carburetor-efi-fuel-and-exhaust/77767-exhaust-gasket-se-or-oem?t=558421)

“The SE ones are preferred by almost every engine builder I've ever spoken to.. More so then any of the aftermarket versions.. They are generally much better at sealing and last longer then the stock ones.”

“The Factory seals are a total Nightmare ! I have been struggling with this for months. The Standard seals are IMPOSSIBLE to get into the head, And the Manual says to put them on the pipe first.” (Note: It is better to install in the heads rather than on the pipe.)

“I changed to the SE seals and there is not much material in them compared to the stockers.”

“I used copper crush gaskets, they are difficult to line up but once good they seal tight.”

“I don't get it, I have swapped back and forth from SE to stock depending on pipes for years and never had an issue intalling the stock gaskets. Yes they are more difficult than the SE but you just work them in one edge slightly in then in a circle pattern until just the edge is in all the way around then keep pushing them in in the same manner until they are seated. Then I take and run my thumb all the way around the inside to make sure they are completely smooth. When installing the exhaust you do so CAREFULLY. Leave the clamp out of the way and pull the heat shields if you can't see up there perfectly. Center the pipe in the gasket and hold tight, slide up the clamp, install the nuts and tighten them evenly. Then again the SE ones work good too and are easier to install. I think if the stock head pipes are on it and you can get the stock seals installed and done correctly that they will last longer, but hey to each is his own.”

There is a Jims (#788) Exhaust Seal Installation Tool: (Sportsterpedia Tool Section for Jims #788)

| Stock HD Exhaust Port Gasket (65324-83B) Notice that the gasket is tapered. Tapered side should face out toward pipes. |  |

| Cometic (bottom) versus HD (top) exhaust gasket comparison. 3) |  |

| Scremin Eagle Exhaust Port Gasket (17048-98) Notice that the gasket is squared off. |  |

| Aftermarket Copper Ring Exhaust Port Gasket Essentially an o-ring shape. |  |

Exhaust Pipes & Cams - Power or Reversion

All exhaust systems have harmonic pressure waves passing down and up the pipes. These waves are initiated by the operation of the exhaust valves. The waves move back and forth, with new waves combining or competing with the existing waves in the exhaust system, to either help move the exhausted mixture out of the pipes or back toward the cylinder. In a complicated way, the rpm of the engine is creating a certain frequency of new waves while the length and shape of the exhaust system is reflecting those waves at its own frequency.

This complex combination of frequencies causes each exhaust system design to have it's own characteristics of helping the combustion cycle at certain rpms (making more power) and hindering that cycle operation at other rpms (creating reversion and less power). The trick is to match the right exhaust system and cams so they are working together to efficienctly create the most power.

Back Pressure is NOT a good thing. But it may come along with other efforts to make a good exhaust.

Quoting Aaron Wilson from the XLForum (aswracing):4)

Reversion is caused by positive pressure from the exhaust during overlap. How is it exactly that “back-pressure” cuts down or prevents reversion? (Note: It doesn't.)

Nobody attempting to find some virtue in “back-pressure” has yet to explain how it would be advantageous to a four-cycle motor to have the exhaust pushing back at any point in the exhaust cycle, other than the comment about preventing draw-through. My question still stands.

The fact is, you want negative pressure in the exhaust system while the exhaust valve is open, especially during that critical window in time called overlap, where both valves are open.

Exhaust systems, by their nature, generate both positive and negative pressure waves that move up and down the pipe, reflecting and changing polarity at both ends. What the pipe designer tries to do is make the negative waves arrive at the chamber during the time the exhaust valve is open, and expecially at overlap, and positive waves arrive while the exhaust valve is closed, where they do no harm. That's done with diffusion devices (baffles, megaphones) to broaden the negative wave such that it arrives over a wider rpm range, and with the length of the system to vary the timing.

Devices that provide diffusion or alter timing while introducing “back-pressure” will incur some pumping losses. But the wave timing is the dominant effect. So even though the back-pressure is a bad thing, it's more than made up for by the corrected wave timing. Back pressure is not what helps, it's a bad side effect of what helps. But if you can provide the proper wave timing without introducing back pressure, it runs even better. That's very difficult to do on a motorcycle, running at low rpm, where the system needs to be long and space is at a premium.

And 5)

I think we can all agree that, while the exhaust valve is closed, it's pretty irrelevant what the exhaust system is doing.

What I'd like to know is when, during the period of time that it's open, it would be a good thing to have the exhaust system pushing back?

The exhaust valve opens roughly two thirds of the way down on the power stroke. It opens early like this because there's still some pressure in the cylinder, and this pressure will help get the spent exhaust gases moving. The rod angle is such that the pressure isn't really helping turn the crank anymore anyway.

The valve remains open as the the piston goes through bottom dead center. All you're trying to do here is empty the cylinder. You don't want anything pushing back.

By the time the piston starts coming up, the pressure has been relieved, and now the piston starts shoving the remaining spent exhaust out. Again, you don't want anything pushing back. You're pushing the gases out.

As the piston nears top dead center, the exhaust valve starts closing. But you really don't want it closed until all the exhaust is out.

Then the intake valve starts opening. You REALLY don't want the exhaust pushing back now. It'll push back right into the intake tract, shoving the charge back out the carb.

Now you've got both valves open, and the piston passes through top dead center. The piston starts down and starts pulling. But both valves are still open! Which port will it pull from?

You've got a cold, dense charge sitting still in the intake tract at near atmospheric pressure. You've got hot, high pressure sitting in the exhaust. Why doesn't it pull from the exhaust? Especially if the exhaust has “back pressure”?

Now the exhaust valve closes and the exhaust system becomes irrelevant again.

I didn't see anywhere in that whole exhaust cycle where it would've been helpful to have the exhaust system pushing back.

An XLForum discussion about stock 'D' cams versus Andrews 'N4' cams:

Quoting Aaron Wilson from the XLForum (aswracing):6)

Well, contrary to what you might hear, the N4's are quite capable of delivering more bottom end than the stock D cams. The reason is that they have overlap, where the “D” cams have very little.

Overlap is the period in time when the exhaust valve is almost closed and the intake valve starts to open. There's a window of time when both valves are open. The piston passes through TDC during this window, finishing it's exhaust stroke and starting it's intake stroke.

Imagine what's going on right then. A whole bunch of hot, high pressure exhaust has just left the cylinder. Sitting in the intake tract is a fresh, relatively cool, air/fuel charge sitting at low pressure. Both valves are open.

The piston starts down, and starts pulling. Where is it going to pull from? The answer is that it wants to pull from the exhaust. That's where all that hot, high pressure is sitting.

So what makes it pull from the intake instead?

It's extremely critical that the exhaust system creates a suction wave right then. If it does, the suction wave will actually pull on the intake tract (remember, both valves are open) and get that fresh charge moving before the piston even starts pulling on it. If the exhaust system does this, it greatly helps cylinder fill.

On the other hand, if the exhaust has high pressure right then, it'll actually push the intake charge back out the intake tract, really screwing up the cylinder fill. What's more, the intake charge will go back out the carb. Then when the piston goes down and the exhaust valve closes, the piston will pull on the intake again. The intake charge ends up passing through the carb three times: in, out, and back in again, picking up fuel each time.

This phenomenon is called a “reversion” and it's readily identified by a dip in the torque curve (a torque curve is essentially a map of the cylinder fill) and a rich area in the a/f ratio. Also, you generally see a fog just outside the carb opening (called a “stand-off”).

The bottom line is that overlap connects the intake to the exhaust, and as such, gives the pipe a lot of control over the cylinder fill. When you put those N4's in your bike, you're going to be making the exhaust system really, really critical.

From 96-02, Buell made a lot of bikes with N4's in them from the factory, and also a lot of bikes with “D” cams factory. The N4 equipped bikes (S1's, X1's, S3's) had a huge hole in the middle of their powerband, because the factory pipe reverted like a bitch through the midrange. The M2 didn't have this hole, even though it had the same exhaust, because it's “D” cams had so little overlap. So as delivered, it was the torque bike, and the others were high horsepower bikes (the pipe pulled at high rpm).

HOWEVER, the Buelling world quickly figured out that by replacing the factory muffler on their S1/X1/S3 with a good aftermarket piece, they could fill in that hole in the powerband, and when they did, it was actually stronger through the midrange than an M2 with the stock pipe. The fact of the matter is that overlap with a pipe that's pulling is a good thing; it helps cylinder fill greatly. Even though the intake close timing of the N4 is biased up the rpm range, it was making more torque than the “D” cam equipped M2 because the extra overlap coupled with a pipe that pulled through the midrange more than made up for it.

So in summary, I'd say yes, the N4's are an excellent choice, but be sure your pipe works for you, and not against you. I really like Supertrapp 2:1's myself, for street use.

(end quote)

Quoting Aaron Wilson from the XLForum (aswracing): 7)

With respect to your question on the powerband, it has an enormous amount to do with the pipe.

The N4's have massively more overlap than the D's. So the pipe is going to be in control.

If your pipe is pulling hard at low and mid range, you're actually going to gain power in the low and mid range. Basically, wherever your pipe pulls, that's where you'll have power. If the pipe pushes back at some rpm, though, these cams are going to cost you a bunch of power there.

The shape of the torque curve tells the story. It's a map of cylinder pressure, which for all intents and purposes is a map of cylinder fill. A perfect torque curve is table flat. Where it comes up from that tends to be where the pipe is working. Where it drops from that tends to be where the pipe is pushing back. When it's pushing back, the afr also tends to go rich.

(end quote)